Production Operation - Thomas O. Allen and Alan P. Roberts

Handbook ProduksiPREFACE

The second edition of production operations includes

revision and updating of many chapters in volume 1 and 2. In volume 2, a new

chapter entitled “Paraffin and asphaltene deposition, removal and prevention”

has been added. Major revisions have been made in the corrosion chapter, with

extensive technical coverage of coating and plastic pipe. Appendices covering

rock mechanics and oil field polymers have been added to the fracturing

chapter. Because an ever-increasing number of universities and colleges in the

world employ OGCI’s production operations books as basic text in production

operations, the second edition includes additional clarification in major

technical areas as well as required technical updating

In an overview of the oil industry, well completion,

workover, and stimulation seemingly plays only a small part. The same is true

even if we limit ourselves to the exploration and production phases of the

industry. From our vantage, however, the focal point of exploration and

production is successful well completion that obtains, and maintains, effective

communication with the desired reservoir fluids. The technology required for

effective well completion involves many disciplines and many different types of

talents. A well completion is not merely a mechanical process of drilling a

hole, setting casing, and perforating a hydrocarbon section.

The importance of total reservoir description; the role of

effective communication between the reservoir and the wellbore; the hazards of

flow restriction around the wellbore; the importance of knowing where fluids

are and where they are moving to; and the rigors of excluding undesirable

fluids all become more and more evident as we move deeper into the areas of

enhanced methods of maximizing recovery of increasingly valuable hydrocarbon

fluids

In preparing production operations, volume 1 and volume 2,

we have tried to logically separate well completion and well operation

technology into packages to permit detailing the more important facets. Effective

well completion and re-completion operation require consideration of specific

problems using all available technology

Volume 1 and 2 are the product of some sixteen years of

conducting training programs throughout the world for industry groups,

including engineers, managers, geologists, technicians, foremen, service company

personnel, and others.

The question is often asked, “what is new in well completion

technology”. Our answer must be that new technology per se is not the real

issue in considering improvement in production operations. “the key to

optimizing oil and gas recovery and profits is the effective application of

proved technology”. This has been the theme of our production operations

courses since our first effort in 1966, and is the theme of these two books on

productions operations. A primary objective of our technical training has been

to assist operating groups reduce the length of them required for “proved

techniques” to become routine field practice

The business of well completion is continually changing. The learning

process continues, technology improves, and just as important, the rules of the

game change with the times and with the area. In many areas, effective and

economic recovery of hydrocarbons from more and more marginal reservoir is the

name of the game. In other areas where costs are tremendous due to

complications of deep wells, offshore activities, or geographic location, high

production rates, which are needed to provide sufficient return on the

incomprehensible investment required, provide the winning combination

Response to the first four printings of production

operations, volume 1 and 2, reflects industry acceptance of our efforts. We anticipate

that the improved second edition will be even more valuable for production

operating personnel than the first edition of production operations. The widespread

awareness of the need to update petroleum personnel at all levels in the

application of proved technology provides OGCI with the incentive to invest

time and money in providing new and improve training course and books. To meet

this need, OGCI is offering additional course each year and is in the process

of developing a series of technical books for the petroleum industry

May 1982

Penggunaan Packer (Seal)

Kampus ProduksiAlasan Utama Penggunaan Packer

- Proteksi casing, Packer mengisolasi dan melindungi casing dari fluida sumur yang korosif dan tekanan tinggi.

- Safety, Packer membatasi area tekanan yang bekerja (well control), dari tekanan pada area diameter casing menjadi tekanan hanya pada sekitar diameter tubing.

- Konservasi energi, Packer mengalirkan seluruh fluida reservoar melalui tubing, dimana gas dan minyak menyatu sehingga menyebabkan daya angkat (memanfaatkan tekanan gas) dalam kecepatan yang tinggi, packer juga dapat membatasi zona- zona produksi sehingga dapat mencegah kehilangan / kerusakan reservoar sumber fluida tersebut

- Kondisi operasional, Terkait dengan alasan operasional penggunaan packer antara lain : alasan produksi (gas lift / hyd pump) dimana dibutuhkan volume annular tertentu yang terbentuk oleh packer, tubing dan casing, alasan cementing, acidizing dsb... (WO & WS)

BACA JUGA:

Jenis & Karateristik Packer

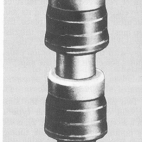

Menurut konsep, fisik dan konstruksi packera. Cup Type Packer

Merupakan bentuk paling standard dari packer, dimana seal berbentuk cup yang bsa menahan tekanan dari 1 arah atau 2 arah secara bersamaanb. Tension Packer (slip/jay - slot combination)

packer yang diset degnan tension, tubing ditarik dengan besaran over pull tertentu yang akan menyebabkan rubber packing mengembang/pack off terhadap casingc. Solid - head compression packer

packer yang diset dengan kompresi, tubing ditekan dengan besaran tertentu yang akan menyebabkan rubber packing mengembang/pack off terhadap casing.d. Isolation Packer

Packer yang diset dengan tujuan isolasi yang ditunjukan dengan adanya pipa/ tubing anchor yang menerus kebawah packer untuk kemudian dikoneksikan dengan packer yang lain.e. Control Head Compression Packer

packer yang menggunakan valve pada control head compression yang bertujuan untuk menanggulangi masalah - masalah pressure dan memungkinkannya tubing dicabut tanpa harus release packer.f. Treating compression packer

packer yang diset dengan fitur tertentu dimana ada tipe ini terdapat kemampuan untuk menahan pressure dari bawah tanpa bergantung pada berat tubing.g. mechanically set dual slip packer

packer yang diset ketika berat tubing tidak mencukupi untuk set packer akibar titik set packer yang lebih tinggi serhingga tidak ada tubing di bawah packer, dimana dilengkapi slip diatas dan dibawah packer yang memungkinkan menahan pressure dari dua arah.h. Hydraulic packer by tubing pressure

Packer yang diset dengan memanfaatkan tekanan dari dalam tubing dengan dibantu plug/ bila sehingga tekanan akan melalui setting port kemudian menekan pistoni. retrivable, permanent packer / drillable

packer yang dilengkapi dengan dua slip atas bawah yang bisa dilakukan pengesetan secara mekanik, hidrolik bahkan wire line. biasanya pada bagian atas terdapat check valve untuk menahan pressure dari bawah dan bisa diset dengan stinger pipe/tubingSeparator Berdasarkan Bentuk Dan Pemisahannya

Kampus Produksi |

| www.pacificproeng.com |

Jenis-jenis separator pada setiap pabrik maupun kilang memiliki bentuk dan cara pemisahan yang berbeda-beda. Sehingga, kali ini penulis akan mengulas salah satu peralatan di kilang minyak ini. Tentu anda pernah mendengar nama alat tersebut, namun sebagian dari anda mungkin belum tahu mengenai fungsinya, dan bagaimana cara kerjanya. Di bawah ini adalah penjelasan mengenai fungsi separator dan cara kerjanya.

Penggolongan Separator Berdasarkan Bentuk dan Cara Kerjanya

- Metode penurunan tekanan.

- Metode turbulensi aliran atau perubahan arah aliran.

- Metode grafiti sentrik.

- Metode pemisahan dengan cara pemecahan fluida.

3 Jenis Separator Berdasarkan Bentuknya

1. Separator Vertikal (Tegak)

2. Separator Datar (Horizontal Separator)

3. Separator Bulat (Spherical Separator)

5 Jenis Separator Berdasarkan Pengaplikasaiannya

- Gas Scrubber

- Knock Out

- Flash Chamber

- Expansion Vessel

- Chemical Electric

Baca Juga : Penggunaan Packer (Seal)